- The Testman's Corner

What is a clean room?

A clean room is a room where the concentration of particles is controlled for a specific scientific or industrial research purpose.

A precise level of temperature, humidity and relative pressure is also maintained (defined according to the ISO 14644-1 standard).

Tame-Test clean rooms are dedicated to implantable medical, space and microelectronics products.

What is the purpose of a clean room?

Used in areas sensitive to environmental contamination, clean rooms are found in the following domains (non-exhaustive list): biotechnology and other areas of biology, spacecraft construction, preparation of sterile pharmaceuticals, construction of optics or micro-mechanisms, in hospitals for operating rooms or for bacteriology, and also in medical research for manufacturing radionuclides.

Why do these fields need a specific environment?

The size of the objects and substances handled is in the micrometer or nanometer range and the particles present in non-purified air can be much larger and can settle on them.

Some chemical or bacteriological experiments can also be dangerous for humans or the environment, this type of work is potentially sensitive to variations in pressure, temperature, humidity or to the presence of gases, chemical vapors or radioactive material for the manufacture of isotopes for example.

We can also control lighting for ultraviolet sensitive operations, and impose nuclear ventilation and radiation protection requirements.

How does a clean room work?

Air entering clean rooms can be filtered to varying degrees of unwanted particle size.

For this purpose, high efficiency particulate air (HEPA) filters are used.

In order to prevent the filters from clogging prematurely, the air is drawn into the room from below, filtered again in an air handling unit (AHU) and then returned to the room, usually from above.

Thanks to this top-down air flow, the total air volume in the room is renewed up to 60 times per hour.

Finally, to avoid the concentration of CO2 released by the people working in the room, and to compensate for the door openings, 30% fresh air is added per hour, filtered by the same recycling process. The air will then be totally new in some areas.

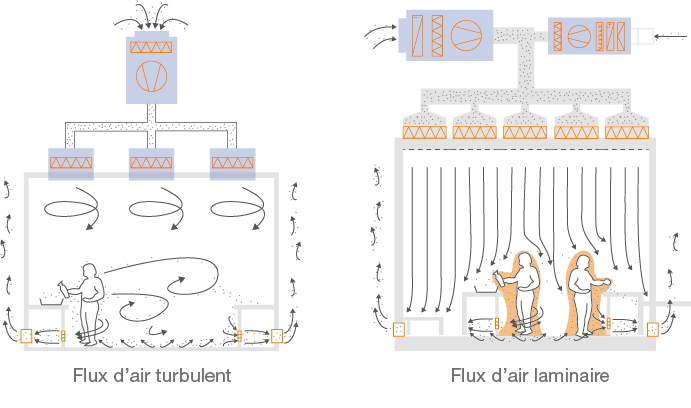

We must differentiate two main types of rooms:

- Rooms in high pressure (compared to atmospheric pressure) in order to prevent various pollutants from entering, mainly found in the pharmaceutical and electronics industry

- Rooms in low pressure (compared to atmospheric pressure) in order to prevent various contaminants from leaving. In this context, the contaminated air passes through a very low penetration filter to be evacuated to the outside

Our three Tame-Test clean rooms fall into the category of high pressure rooms.

The entry and exit of personnel into and from the clean rooms is carried out through one or more airlocks, sometimes equipped with an air or water shower, and changing rooms.

Why is this so?

Because the human body is a nest of contaminants such as hair, dead skin cells, etc. Operators in the clean room must therefore be equipped with specific clothing that is more or less strict depending on the degree of contamination and dust tolerated.

This equipment may include a suit, a head covering, gloves, slippers, a mask, specific undergarments, or even a full suit.

Inside the room, the tools used are carefully selected to generate few particles.

Air flow in the clean room

Here we see the flow diagram of a clean room. For Tame-Test’s clean room dedicated to medical implants, it is in laminar flow under a hood in ISO 5.

Classification of the particulate cleanliness of the air

If only one control parameter is to be retained, it is the quantity and size of dust per unit volume.

Clean rooms are classified according to the number of particles per unit volume.

To carry out these measurements, we use a measuring device: the particle counter, which will count the number of particles in a given volume and thus determine the class of the clean room.

Our clean rooms are all equipped with ISO 7 filtration.

- Also in The Testman's Corner