Tune range

Test benches for adjustments and calibrations

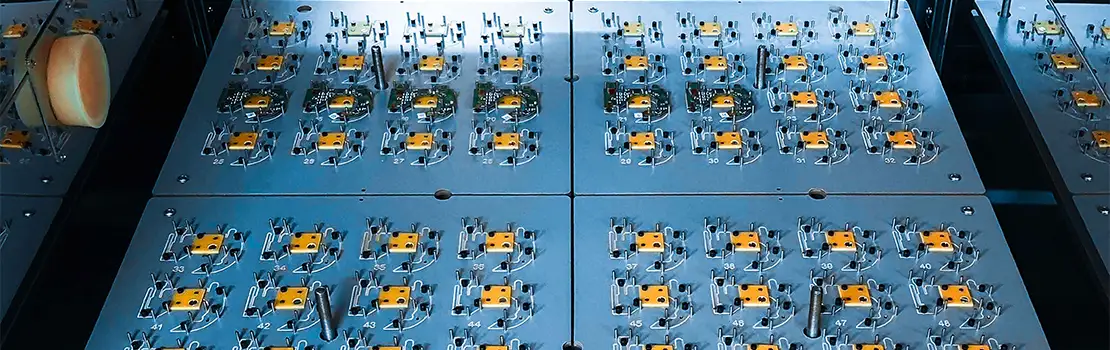

The Tune line of test benches is designed to carry out adjustment, calibration and characterization tests.

These tests can be performed on an electronic card, a set of cards, or on finished products.

In addition to the models intended for production lines, these benches can be mobile and energy autonomous (the Tune Field line).

Technical specifications

Why choose this product?

The test functions available in the Tune line of test benches vary according to your needs:

- Characterization of sensors

- Adjustment of multi-physics acquisition systems

- Frequency adjustment

- RF circuit tuning

Who is it for?

The Tune line of test benches is aimed at any company wishing to adjust, calibrate and characterize their products and who have a high demand in accuracy and user-friendliness. The offer is aimed at both start-ups and large industrial companies, whatever the field of activity (medical, aerospace, and more).

In which environment?

Tune benches are designed to adapt to your environment: laboratories, production plants but also clean rooms.

At what point?

- During the production cycle, for product tuning/calibration in final factory inspection

- During commissioning

- During the product’s life cycle for its periodic inspection/verification (between metrology phases for example)

- During the development phase of the product

Technical functionalities

Adjustment

This type of bench allows you to fine tune your product. Examples of applications are:

- Fine tuning of a frequency

- Tuning of RF circuits

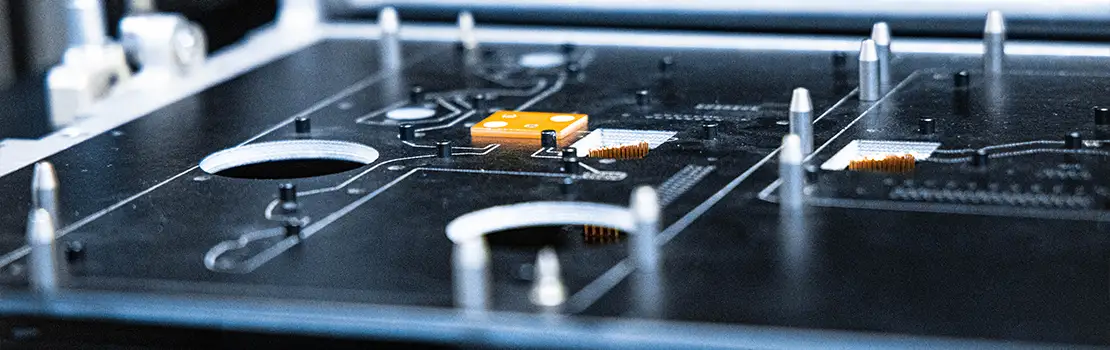

Characterization

This type of bench allows you to characterize your product. Examples of applications are:

- Characterization of the coefficients of a sensor acquisition system (pressure/temperature)

- Storage of the calculated coefficients in a test report and/or in the product under test

Calibration

Calibration of the measurement chain of the product under test

Applications of Tune range

In order to gain a better understanding, here are some use cases illustrating this equipment:

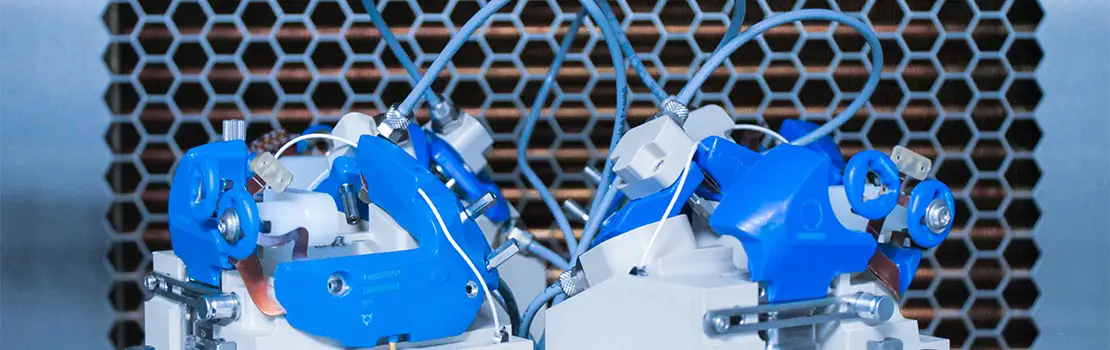

Use case n°1: Radar for the Protection of Sensitive Sites

Kate is responsible for the installation of anti-intrusion radar for a manufacturer of surveillance equipment. She wants to set up a test to calibrate the radar based on the environment and the shape of buildings and other sites.

Tame-Test proposes a Tune tester that is compact and adapted to the field, embedded with useful instrumentation and that is transportable and autonomous. After deploying a mast, several parameters will be measured in all directions. The coefficients will then be programmed into the product. This radar will thus be optimized for the environment in which it is installed. Tame-Test’s Tune test facilities will have made the deployment operations much faster, less expensive and, above all, repeatable.

Use case n°2: Active Implantable Medical Device

Simon, founder of a medical startup, is the inventor of a medical device for heart failure. One of the key parameters of his device is the accuracy of the pressure measurement. The pressure sensors used for its design require an adjustment of the acquisition system in which they are located because the other components, or a material of this system, influence the value. The precision of the adjustment is very high, in the order of a tenth of a millibar.

Tame-Test proposes and develops an automatic TUNE tester used in series and with the ability to simulate Simon’s Device. It will be able to carry out all the measurements of the Pressure/Temperature pair at different values and around the operating point of its acquisition system. This industrial tester, in addition to the electrical, electronic and software aspects, is implemented in all the pressure management aspects (control, measurement, conduits…). This bench is designed so that the interface is placed in a constrained and controlled environment (climatic enclosure with control and variation of temperature and humidity). According to the real measurements in this constrained environment and the measurements carried out by the medical device, the TUNE bench will inscribe the adjustment coefficients into the product via a specific test software. Measurements are then carried out to validate that the product takes the same values as the real measurements. As these real measurements are carried out by equipment subject to metrology, Simon gains great confidence in the results of the pressure values indicated by his equipment. This bench will then be followed up on by Tame-Test via its LifeSolution service in order to maintain this confidence.