Remedy range

Industrial test benches for fault diagnosis

What is fault diagnosis?

In production phases or in after-sales service, fault diagnosis consists in determining the precise origin of a malfunction.

This process has several levels of complexity. For a system made up of several sub-assemblies, it is be necessary to determine which is, or which are, the sub-assemblies responsible for the symptoms. Then, we must look at the faulty sub-assembly to determine the responsible electronic card and do the same on this card to identify the root cause of the failure.

Some causes of failure are very complex to identify and require an in-depth knowledge of the defective product right down to its design origin. Experienced engineering and even the designer are regularly called upon to solve the equation and find the solution.

Technical specifications

The objective of our Remedy line is to provide precious help in this complex process of fault diagnosis. Both at the level of electronic cards and assemblies.

Why?

The Remedy line of equipment brings autonomy to production and diverts the need to call on the designer for fault diagnosis.

In this line, particular attention is paid to the design of interfaces, tools and test software in order to have full access to the product and to be put in the same conditions as the failure.

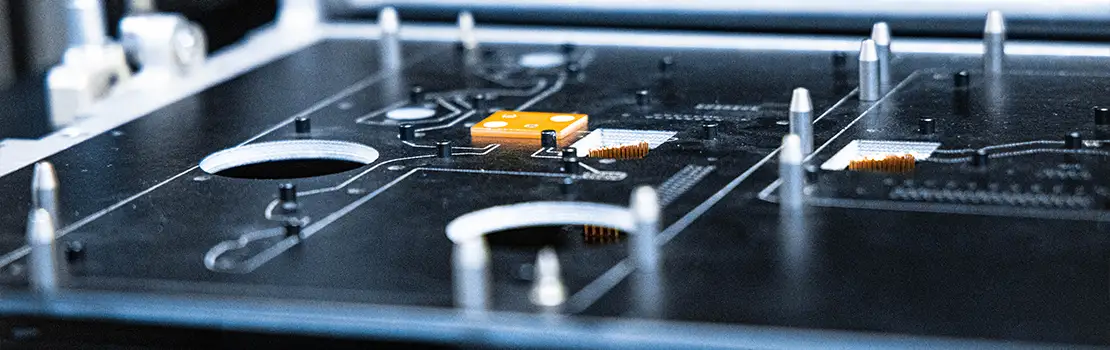

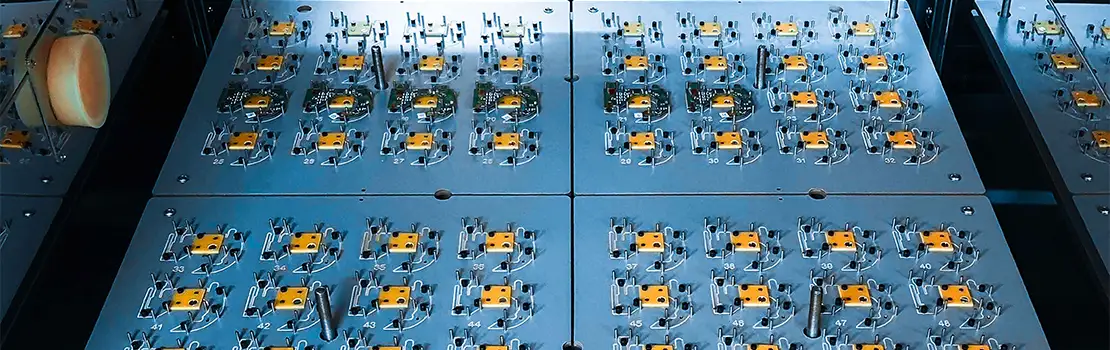

The interfaces can be designed to position electronic cards vertically, allowing access to both sides. The different cards constituting a system can be implemented on the same interface in order to reproduce it in an “exploded” way and thus highlight the failure in its environment.

As for the software, it is designed to:

- Examine the detected fault while keeping the testing conditions

- Manipulate access parameters (change the measurement path for example)

- Manipulate power supplies

- Manipulate devices and equipment (parameters, measurement triggering, etc.)

- Send frames to the equipment under test and read the feedback

- Program the product with a previous version or a version for the test

- Close a test at will

- Run a test alone

- Inject errors (hardware, software, emulator, etc.)

- and more

Our Remedy test bench is also available in Remedy Labs. In this case, it is designed specifically for the repair of small series and is entirely manual.

Its main objective is the direct access to the equipotentials allowing for a quick diagnosis of the failure.

It is common for Remedy Labs to be derived from a recycled Check Labs design validation test bench, initially intended for small series production. This avoids a new development and the associated costs.

The Remedy line can be stationary when it is intended for a dedicated production workshop or mobile, even portable, when it is intended for field use.

This line is also adaptable to very high power products (several hundred volts and/or amps). In this case, it must be used by an authorized technician and will be equipped with additional protections.

Which environment?

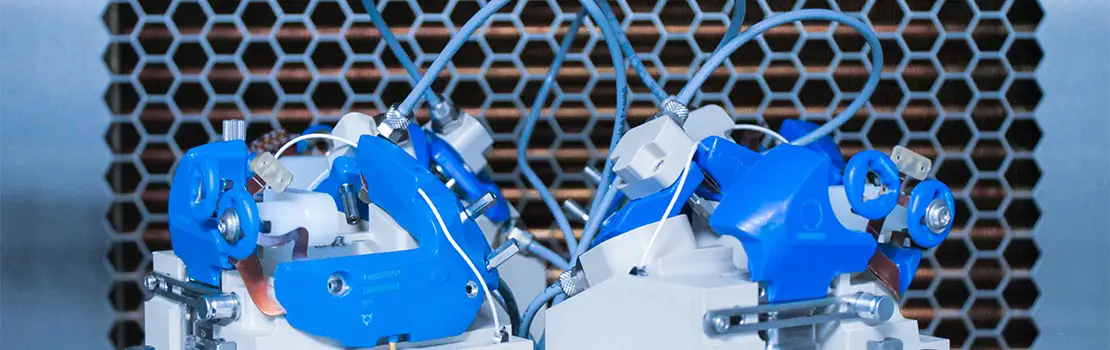

Some failures are only reproducible in a specific environment, for example temperature. The product works perfectly at room temperature but malfunctions at high temperatures. Remedy benches are equipped with an optional arm that allows hot air to be blown locally on the product to identify the faulty area.

Remedy benches can be equipped with various accessories, such as motors, sensors, batteries or other diagnostic elements.

Applications of Remedy range

In order to gain a better understanding, here are some use cases illustrating this equipment:

Use case n°1: Medical Controller

Youssef, production manager of a large company manufacturing an automatic medical system, is faced with a large number of failures in production because his product and his manufacturing process are both very complex. His product includes several types of electronic cards. Tame-Test has developed for Youssef a tester from the REMEDY line that can accommodate either his system or the electronic cards that make it up (on a single interface). Tame-Test has developed the Remedy bench software so that it is fully configurable by the user by including functions specially dedicated to the simulation of failures. Youssef’s teams will then drastically reduce the time spent on diagnosis. After each product that is repaired, they will be able to record the replaced component(s) in the Learn application of the Tame-Data software suite, indicating which measurement was wrong before the repair. Over the course of diagnosis and repair, combinations will appear (bad measurement/faulty components). The Learn application will then be able to restore these combinations and thus guide Youssef’s collaborators towards a quick diagnosis (for such a KO measurement, such a component or such a sensor have been replaced in most cases).

Use case n°2: Aeronautical Card with an ARINC Bus

Marie-Hélène, in charge of the test workshop of an electronic subcontractor, encounters failures on an electronic card designed for an ARINC bus. It is difficult to access the card and the bus driver on a functional tester, designed to test electronic cards in series. Tame-Test adapts a solution from its REMEDY line to Marie-Hélène’s needs by proposing a vertical positioning of the card to access its two sides. This REMEDY solution will also be equipped with a panel of connectors to connect to each of the bus signals. What a time saver for Marie-Hélène’s staff!