Rely range

Burn-in testing

What is burn-in testing?

Burn-in is a process that consists in triggering product failures. It is used to test the elements of a system before it is put into service.

The failures sought are the “early failures”, meaning the incidents related to the breaking-in of the system.

This process is widely used in the electronics industry; electronics engineers are experienced in its use.

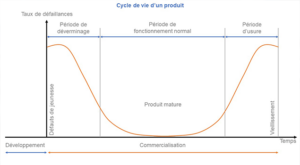

It is said that the life curve of a product is like a bathtub:

The importance of this method is to find the right balance between detection of early assembly failures and aging without altering the lifetime of the product.

Tame-Test can work with you to define and justify burn-in characteristics and profiles. From this study the nature of the burn-in will be derived:

- Burn-in

- HALT

- HASS

- Rapid Variation of Parameters (Temperature, Pressure, etc.)

- Vibrations

Technical specifications

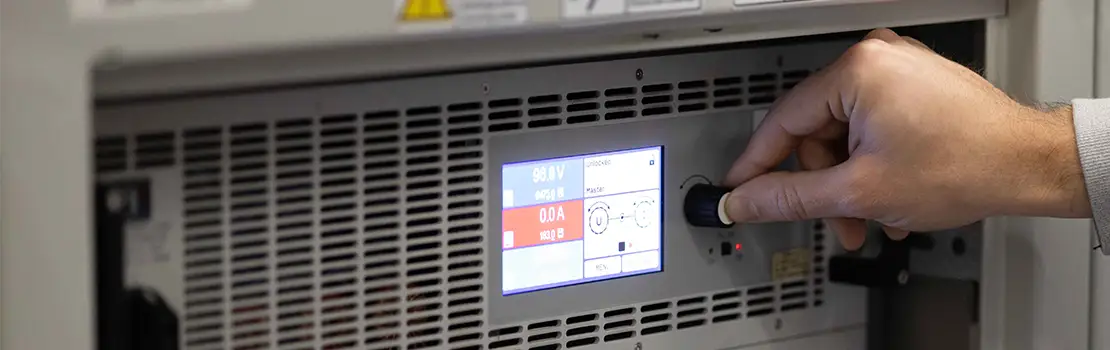

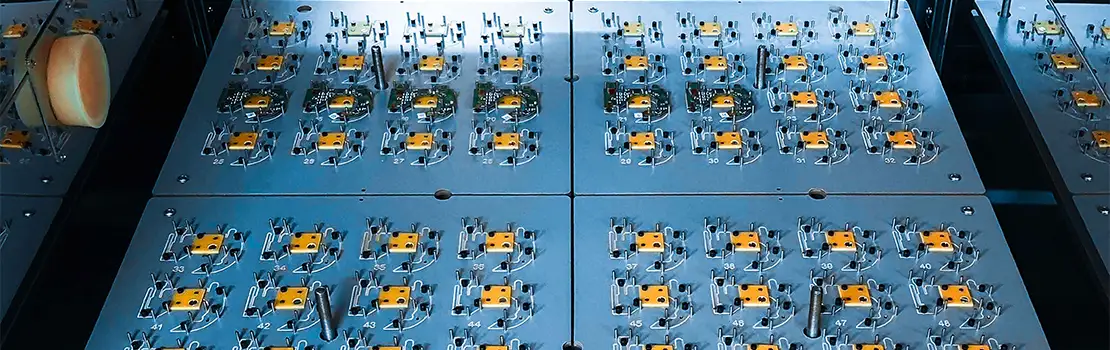

The Rely line of burn-in test benches provides the solution for guaranteeing the reliability of your systems. By prematurely aging and detecting early failures of a board or an assembly, we can directly eliminate them and thus allow you to market higher quality products.

Tame-Test has also developed Rely test benches to test products under pressure, vibrations or even combining certain conditions such as pressure and temperature. These combinations are usually known as HALT and HASS tests.

All input and output data (results) are centralized through a network and analyzed by the Tame-Data software suite.

Why choose this product or this service?

Tame-Test’s “Rely” line of equipment allows markets with high demands in standards to make sure their products are reliable, thus avoiding premature malfunctions that can have serious human or financial consequences.

When to use it?

The Rely line of test benches is not a laboratory tool but a production tool, the aim being to manufacture highly reliable products right from the start of the industrialization process. They are designed to be handled by a simple operator under the supervision of a technician or engineer for measurement analysis.

Technical functionalities

Rely test benches, based on standard technological hardware and software “building-blocks”, automate the process by operating instruments, ovens, shakers or any other necessary element.

These are all sized in order to meet the burn-in profiles determined ahead of time.

Our Rely test benches allow you to test your products for a duration between a few minutes to several weeks.

All input and output data are centralized through a network and analyzed by our Tame-Data software.

Temperature tests

- These tests are adjustable according to the profiles determined in the preliminary study

- They are generally linked to the IEC/EN 60068 standard and its branches IEC/EN 60068-2 and IEC/EN 60068-3

- They are carried out at a constant positive temperature or in Rapid Temperature Variation, with or without a power supply, in continuous testing or not

- The testing temperature must be carefully monitored so as not to be too high and burn the components, but high enough to simulate specific conditions

Pressure tests

- These tests are adjustable according to the profiles determined in the preliminary study

- They are generally used to detect early failures on equipment with pressure sensors or on underwater equipment

- They are carried out at a constant positive pressure or in Rapid Pressure Variation, with or without a power supply, in continuous testing or not

- The testing pressure must be carefully monitored, so as not to be too high or too low and not to damage the sensors and other components, but having a sufficient amplitude to simulate specific conditions

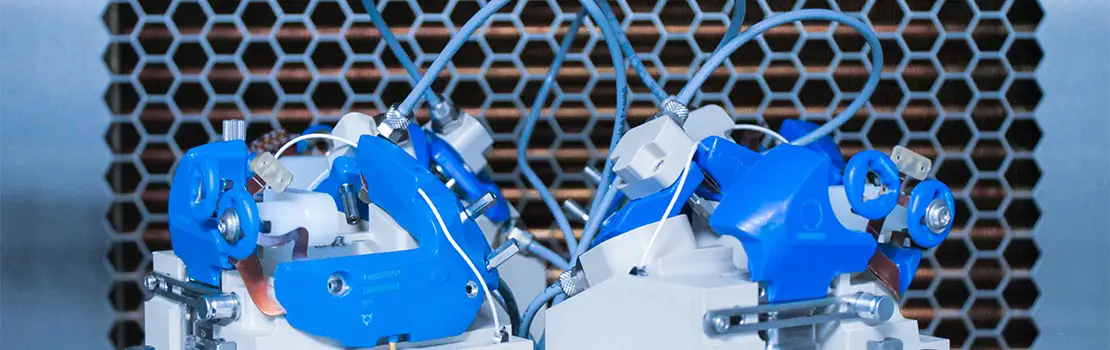

Vibration tests

- Vibration testing of electronics is a very good way to see where the weaknesses are (contacts, soldering, resonances, etc.)

- For the test to be effective, it must be carried out on final equipment because the equipment’s casing (due to its own mass and its mounting/installation) will always modify the equipment’s response to testing

- To proceed rationally, the first point to look at is the standard of vibrations to which the equipment must respond (aeronautical, marine, military, industrial…) which defines the envelopes of acceleration (g) according to the frequency and the type of solicitation: sinus and/or random noise, and all following the 3 axes

HASS tests

Testing by combining several parameters, better known as HASS tests:

- HASS (Highly Accelerated Stress Screening) tests are a series of combined burn-in tests

- During its lifetime, all or part of your equipment is subjected to thermal and mechanical stress with levels of severity being defined by HALT tests (Highly Accelerated Life Test). The methodology of the HASS tests exposes failures related to the manufacturing process.

Applications of Rely range

In order to gain a better understanding, here are some use cases illustrating this equipment:

Use case n°1: Product Embedded in an Aircraft

Mohamed, representing a large aeronautical equipment manufacturer, is developing the manufacturing process for an embedded product. He asks Tame-Test to define and implement the appropriate Rely tests.

Tame-Test will first compile the input data (mission profile of the product, lifetime, environment, etc.). Tame-Test will then define the types and profiles of the burn-in in order to eliminate the early failures of the product and to justify that these burn-in processes do not alter the reliability and durability of the product. Tame-Test can then develop and deploy its equipment from the RELY product line.

Use case n°2: Medical Product

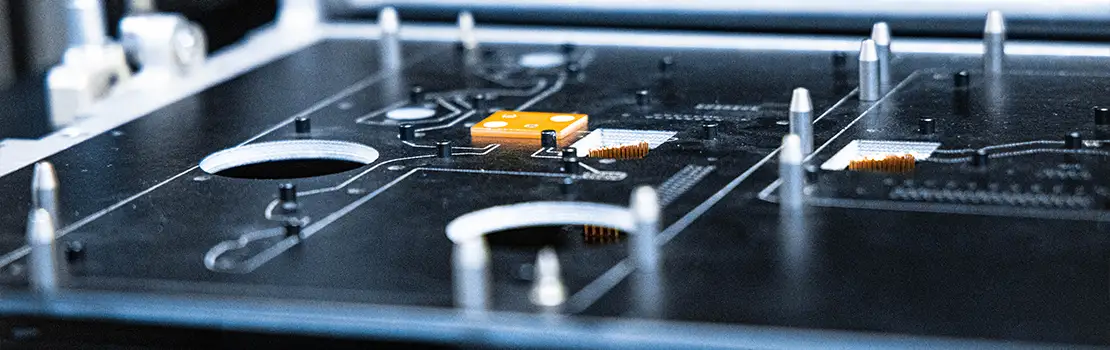

Mia, industrialization manager in a medical startup, is looking for support to start the production of a brand new Active Implantable Medical Device.

The product is composed of several electronic cards and is equipped with pressure sensors, the main element of this product.

Tame-Test will discuss with Mia in order to converge on the burn-in profiles to be implemented in order to eliminate the possible membrane defects on the sensors, stabilize these membranes before calibration, all while eliminating the early failures on the other elements of the electronic cards.

Tame-Test can then develop and deploy equipment from the RELY product line.